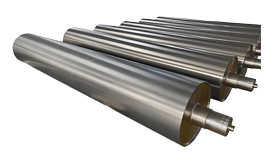

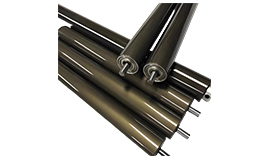

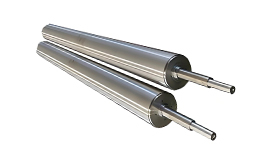

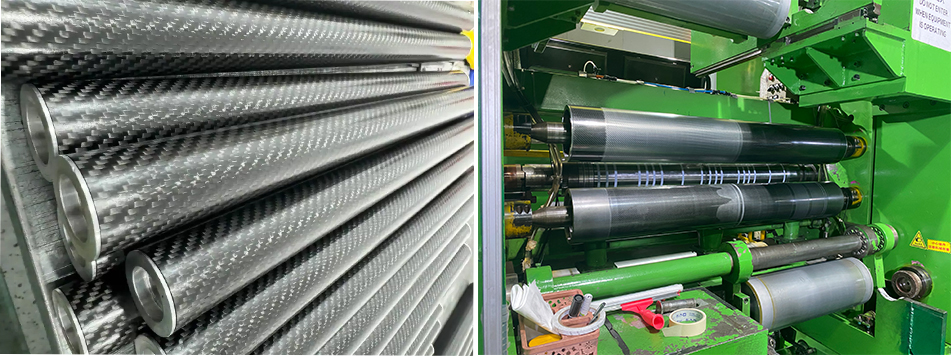

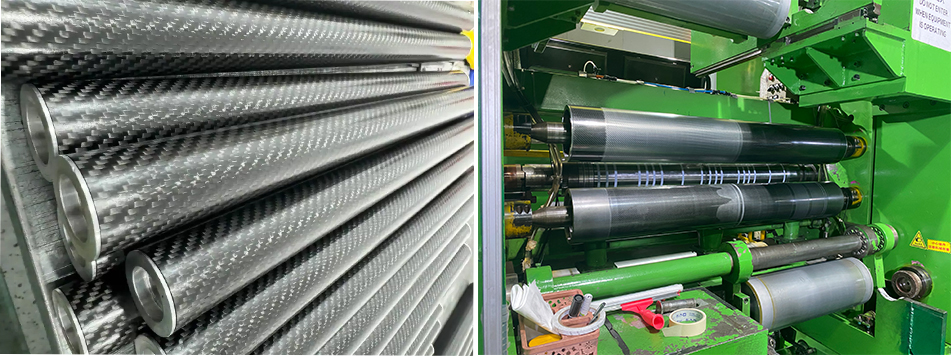

Carbon fiber rollers have demonstrated significant performance advantages in high-end industrial fields due to their unique material properties. The following is a detailed analysis of its core advantages and typical application scenarios:

1. Ultra lightweight and high-strength

Weight ratio: The density is only 1.5-2.0 g/cm ³, which is 30% lighter than aluminum alloy and 70% lighter than steel. At the same time, the tensile strength can reach 3000-7000 MPa (about 5-10 times that of steel).

Application value:

High speed printing machine guide roller: reduces rotational inertia and improves printing speed (such as digital inkjet printing roller speed of over 10000 rpm)

Aerospace composite material laying equipment: reducing mechanical arm load and improving positioning accuracy

2. High rigidity and deformation resistance

Modulus characteristics: The elastic modulus is 200-600 GPa (close to titanium alloy), and the bending stiffness is 3-5 times that of metal rollers.

Technical advantages:

Precision coating machine roller: deformation less than 0.01 mm under pressure of 10-100 N/m ², ensuring coating uniformity (such as lithium battery electrode coating)

Semiconductor wafer polishing equipment: maintain the flatness of the roller surface for a long time to avoid micro scale scratches

3. Excellent thermal stability

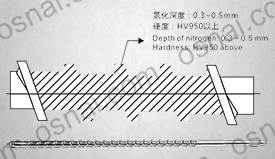

Thermal expansion coefficient: The axial CTE is close to zero (0.1 × 10- □/℃), much lower than that of metal (steel 11.7 × 10- □/℃). High temperature performance:

The thermal deformation of carbon fiber rollers at 200 ℃ is only 1/20 of that of metal rollers, making them suitable for high-temperature shaping equipment such as carbon fiber prepreg hot pressing rollers

Laser cutting machine guide roller: avoid size drift caused by thermal accumulation

4. Fatigue resistance and long lifespan

Cycle life: It can withstand more than 107 cycles under alternating loads, with a fatigue strength of 70-80% of the ultimate strength (usually 30-50% for metal rollers).

Economic performance:

Wind turbine blade production mold roller: life is three times longer than steel roller, reducing downtime and replacement frequency

Paper making machinery drying section roller: resistant to steam heating cycle impact

5. Corrosion resistance and environmental aging resistance

Chemical inertness: resistant to acid and alkali, salt spray, organic solvents, and no risk of electrochemical corrosion.

Special Scenario:

Marine engineering composite material winding machine roller (such as manufacturing ship propeller shaft sleeves)

Chemical pipeline winding equipment: Contact with corrosive media such as epoxy resin and curing agents

6. Dynamic performance optimization

Critical speed: Low density and high rigidity increase the critical speed by more than 50% to avoid resonance.

High speed applications:

Textile machinery high-speed stretching roller: vibration amplitude<5 μ m when speed>8000 rpm

Magnetic levitation bearing support roller: achieving micrometer level dynamic balance accuracy

Typical Industry Applications

1. In the field of new energy: fuel cell bipolar plate pressing roller, photovoltaic silicon wafer cutting guide wheel

2. Rail transit: High speed rail body composite material forming mold roller

3. Medical equipment: CT machine carbon fiber rotating anode support roller (with X-ray transparency)

technological frontier

Nano modified carbon fiber roller: adding graphene to enhance thermal conductivity (>200 W/m.K), used in 5G high-frequency circuit board laminating equipment

Intelligent carbon fiber roller: integrated strain sensor for real-time deformation monitoring and predictive maintenance

Carbon fiber rollers are replacing traditional metal rollers and ordinary composite material rollers as core components in the high-end manufacturing field due to their lightweight, high rigidity, and environmental resistance characteristics.

|