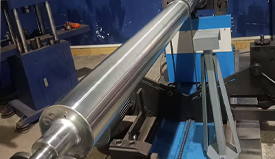

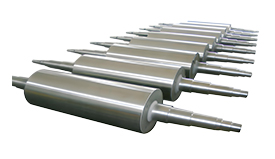

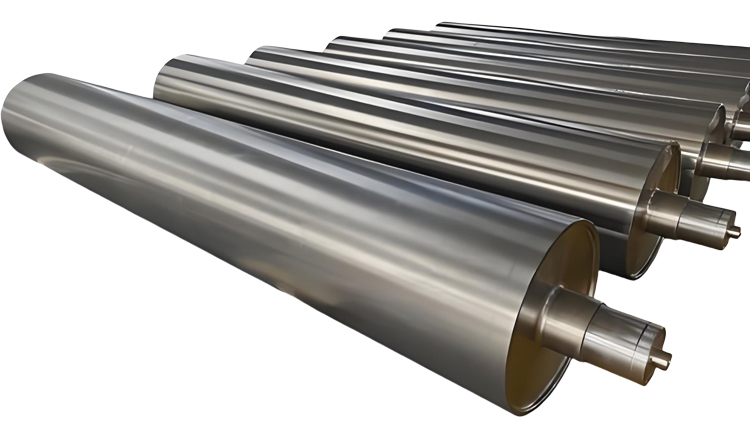

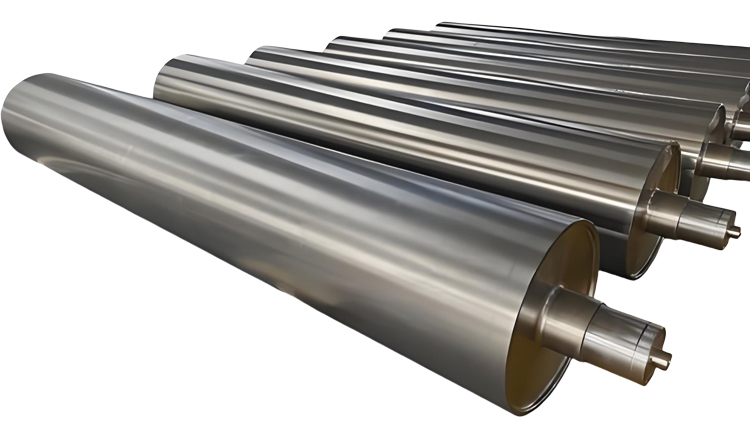

Steel rollers have significant advantages in dynamic balancing and are suitable for various industrial scenarios, especially for applications with high precision, high load, or high-speed rotation

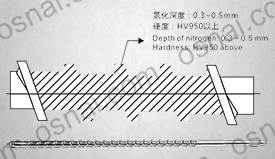

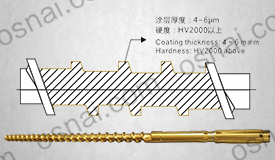

1. Excellent wear resistance

Material characteristics: Tungsten carbide (WC) has extremely high hardness (HRA90 or above), far exceeding traditional steel rollers, and can withstand long-term friction during high-speed rolling of aluminum foil. Reduce downtime: Wear resistance prolongs service life, reduces replacement frequency, and improves production continuity, especially suitable for high load continuous rolling lines,

2. High temperature stability

Heat resistance: During high-temperature processes such as aluminum foil annealing (usually 300-500 ℃), tungsten carbide guide rollers are not easily softened or deformed, maintaining dimensional stability and avoiding uneven thickness or surface defects of aluminum foil caused by thermal expansion.

3. High surface finish and low friction

Precision machining: Mirror level smoothness (Ra ≤ 0.05 μ m) can be achieved through grinding and polishing, reducing surface scratches on aluminum foil.

Reduce friction: Low friction coefficient reduces the adhesion between aluminum foil and guide rollers, preventing material tearing, while reducing energy consumption and improving production efficiency.

4. Corrosion resistance

Chemical corrosion resistance: Strong corrosion resistance in coolant, lubricant or humid environments, avoiding surface contamination caused by rust, suitable for the production of food or pharmaceutical aluminum foil with high cleanliness requirements.

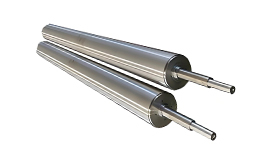

5. High rigidity and precision maintenance

Rigid advantage: high elastic modulus (about 600 Gpa), strong deformation resistance during high-speed operation, ensuring uniform tension of aluminum foil, reducing the risk of wrinkles and breakage.

Long term accuracy: Maintain shape stability during long-term use, suitable for high-precision rolling requirements of ultra-thin aluminum foil (such as below 6 μ m),

6. Comprehensive economic benefits

Life cost ratio: Although the initial cost is relatively high (about 3-5 times that of steel rollers), the life can be extended by 5-10 times, and the long-term maintenance cost is significantly reduced.

Reduce losses: Reduce the scrap rate of aluminum foil caused by guide roller problems and improve the yield rate

7. Environmental adaptability

Multi functional scenario: Suitable for multiple stages such as rough rolling, precision rolling, slitting, coating, etc. of aluminum foil, especially excellent performance in high-speed rolling mills (such as above 2000m/min).

Tungsten carbide guide rollers, with their material properties, have become a key component for improving quality, efficiency, and cost control in high-end applications in the aluminum foil industry, especially suitable for scenarios with strict requirements for surface quality, thickness accuracy, and production continuity.

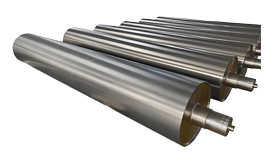

Widely applicable in various fields

Cold rolling: high-precision rolling of stainless steel, titanium alloy, copper aluminum foil, and other materials.

Hot rolling: The stability at high temperatures is better than that of traditional rollers.

Paper/textile: wear-resistant and reduces fiber residue.

Continuous production line: reduce downtime and improve efficiency.

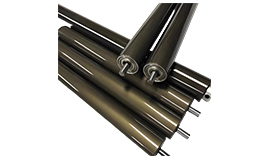

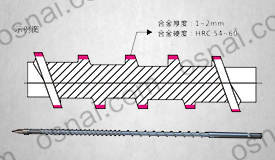

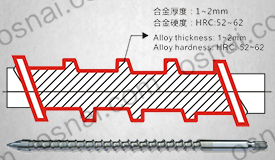

Advantages compared to other materials

VS alloy steel rollers: have a lifespan more than 10 times longer and require less maintenance.

Ceramic rollers: better impact resistance and less prone to brittle cracking.

Vs polymer roller: better high temperature resistance and pressure resistance.

|