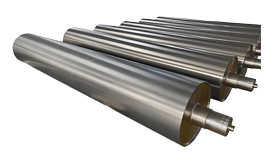

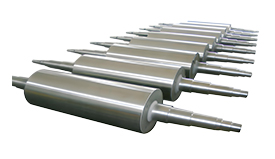

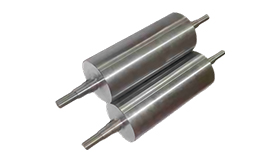

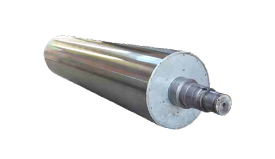

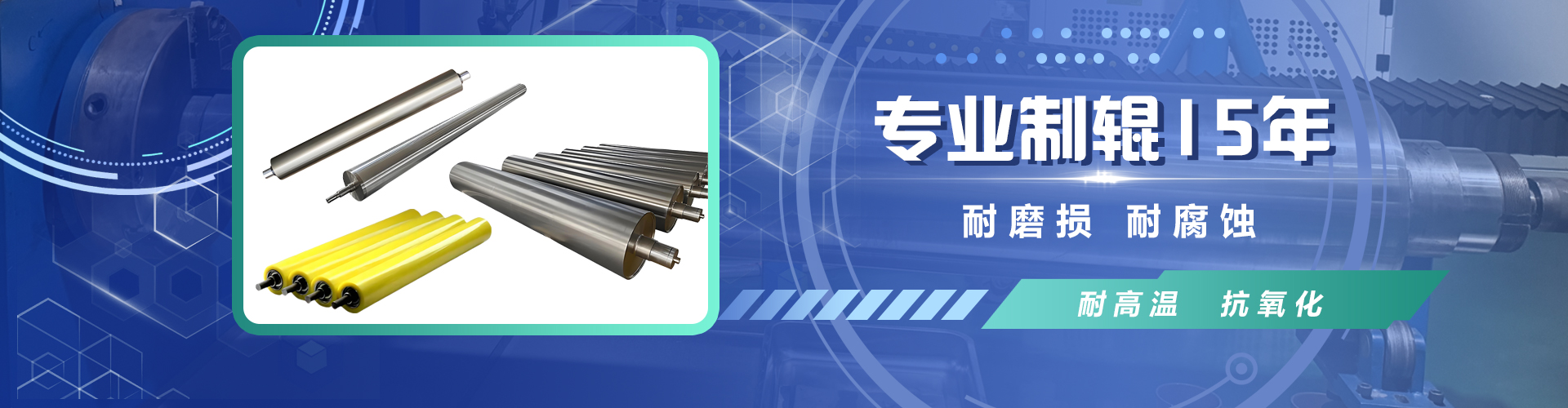

The rolling mill is the core component in a rolling mill, used to apply pressure to metal or other materials, causing them to undergo plastic deformation, thereby obtaining the desired shape, size, or performance. Rolls play an important role in industrial production, with the following advantages and application areas:

Advantages of rolling mill

1. Efficient production

Rolls can continuously and rapidly process metal materials, greatly improving production efficiency and suitable for large-scale industrial production

2. High precision molding

Through precise roll design and control, high-precision, high surface quality sheets, profiles, or pipes can be produced, reducing the need for subsequent processing.

3. Material performance optimization

The rolling process can improve the grain structure of metals and enhance the mechanical properties such as strength, hardness, and toughness of materials (such as through hot or cold rolling).

4. Strong adaptability

Rolls can be used for various materials (such as steel, aluminum, copper, titanium and other metals and alloys) and various processes (hot rolling, cold rolling, warm rolling) to meet the needs of different industries.

5. Energy conservation and environmental protection

Compared to forging or cutting, rolling technology has lower energy consumption and higher material utilization, which is in line with the trend of green manufacturing.

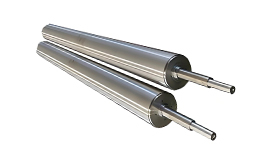

The main application areas of rolling mills

1. Steel industry

Plate production: hot-rolled plate, cold-rolled plate (used for automobiles, ships, household appliances, etc.).

Production of profiles: H-beams, track steels, angle steels, etc,

Pipe production: seamless steel pipes, welded pipes, etc.

2. Nonferrous metal processing

Aluminum plates/foils (such as beverage cans, battery foils), copper strips (for the electronics industry), titanium alloys (for aerospace), etc.

3. Automobile manufacturing

|