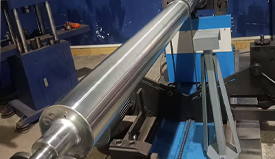

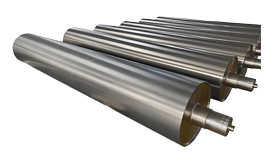

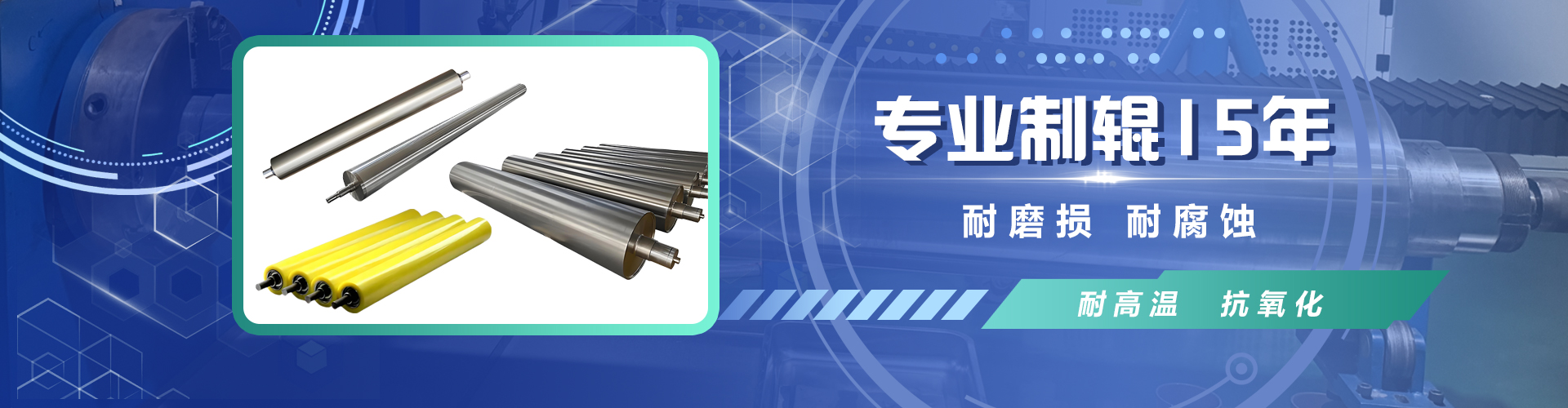

Advantages of chrome plated rollers

Chrome plated rollers (steel rollers coated with hard chromium on the surface) have a wide range of applications in the aluminum foil industry and other metal processing fields, with their core advantages reflected in the balance between economy, surface performance, and moderate durability. Has the following advantages:

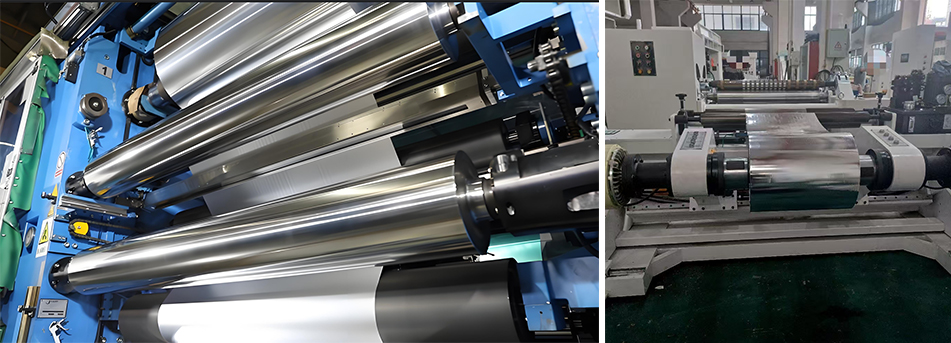

1. High surface hardness and wear resistance

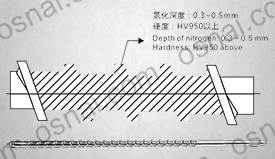

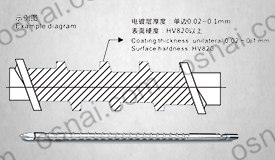

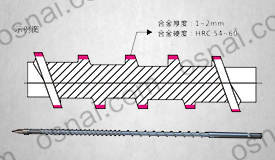

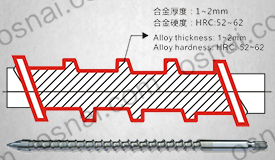

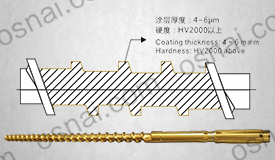

Coating characteristics: The hardness of the hard chromium coating is greater than HV680, significantly higher than that of ordinary steel rollers, and can effectively resist friction and wear during aluminum foil rolling.

Extended lifespan: Under moderate load conditions (such as rolling speed s1200m/min), the lifespan of chrome plated rollers is 2-3 times longer than that of untreated steel rollers, making it suitable for continuous production needs.

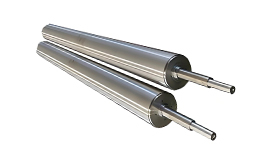

2. Excellent surface smoothness

Low roughness: After precision grinding and chrome plating, the surface roughness can reach Ra0.05-0.1 μ m, close to mirror effect, reducing scratches on the aluminum foil surface, especially suitable for finishing processes before precision rolling or coating.

Low friction coefficient: The smooth chrome plating layer reduces the adhesion between the aluminum foil and the rolled surface, reduces the risk of material tearing, and improves the yield rate.

3. Corrosion resistance and anti adhesion

Chemical inertness: The chromium layer has good corrosion resistance to water, oil, and weak acid/alkaline media (pH 5-9) at room temperature, and is suitable for conventional coolant or lubricant environments.

Anti adhesion advantage: The chrome plated surface is not easily adhered to aluminum powder or residue, making cleaning and maintenance convenient and reducing downtime.

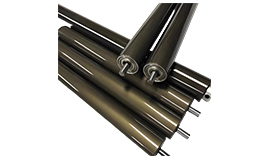

4. Economy and processing flexibility

Low cost solution: The initial cost of chrome plated rollers is lower than that of tungsten carbide guide rollers, and the substrate can be made of ordinary alloy steel (such as 45 # steel, GCr15), which has good economy.

Repackability: After the surface coating is worn, it can be repaired by chromium removal and re electroplating, with a single repair cost of about 20-30% of a new roller, extending the overall service life

5. Wide process adaptability

Temperature compatibility: The chrome plating layer has good stability in environments ≤ 200 ℃ and is suitable for aluminum foil rolling, annealing (low temperature range), coating and drying processes.

Diversified design: The coating thickness (usually 0.05-0.2mm) and substrate material can be adjusted to meet the process requirements of different pressures and speeds.

Chrome plated rollers, with their high cost-effectiveness, excellent surface finish, and moderate wear resistance, have become an ideal choice for medium speed rolling, finishing, and multi variety production scenarios in the aluminum foil industry. Its advantages are particularly prominent in conventional corrosive environments and moderate load conditions, but higher performance rollers are required in ultra high speed, ultra-high temperature, or strong corrosive conditions. Enterprises need to choose chrome plated rollers reasonably based on production scale, environmental requirements, and process parameters to achieve the best balance between quality, cost, and efficiency.

|