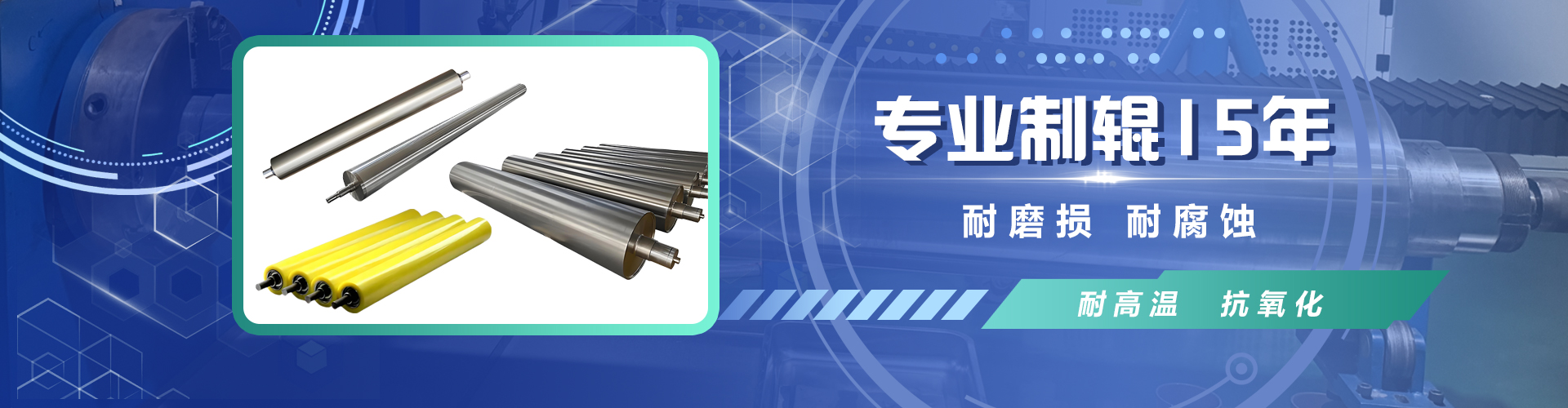

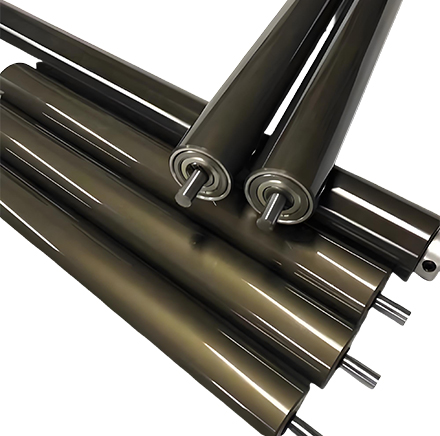

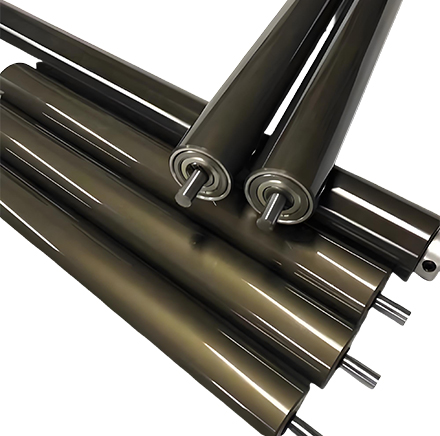

Advantages of anodized aluminum rollers

The application advantages of anodized aluminum rollers in the aluminum foil industry are mainly reflected in their unique surface treatment characteristics, especially suitable for scenarios with high requirements for corrosion resistance, surface cleanliness, and lightweight.

1. Excellent corrosion resistance

Oxide film protection: Anodizing generates a dense layer of aluminum oxide (Al ₂ O3) on the surface of the roller, which has high chemical stability and can resist corrosion from cooling liquids, lubricants, and humid environments, avoiding corrosion and contamination of the aluminum foil on the roller surface.

Clean production: suitable for production lines with strict cleanliness requirements such as food packaging and pharmaceutical aluminum foil, reducing surface impurities on aluminum foil caused by roller corrosion.

2. Smooth surface and low adhesion

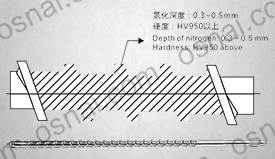

Nano scale microporous structure: The porous membrane formed by anodizing has a smooth surface after sealing treatment (Ra can reach 0.1-0.2 μ m), low friction coefficient, reduces adhesion between aluminum foil and roller surface, and reduces the risk of scratches and tears.

Anti pollution: The oxide layer has strong hydrophobicity and is not prone to residual aluminum powder or oil stains, simplifying the cleaning and maintenance process.

3. Advantages of Lightweight Design

Material characteristics: If the roller body is made of aluminum alloy substrate, it can achieve lightweight after anodizing (reducing weight by more than 50% compared to steel rollers), reducing inertia energy consumption during high-speed operation, and suitable for high-speed slitting or tension control links.

Fast dynamic response: The lightweight roller body is more sensitive during start stop or speed change, which helps improve the tension control accuracy of ultra-thin aluminum foil (such as below 6 μ m).

4. Insulation performance

Non conductive surface: Anodic oxide film has insulation properties, which can avoid aluminum foil adsorption or discharge damage caused by static electricity accumulation. It is suitable for anti-static process sections such as coating and printing.

5. Economy and environmental friendliness

Low processing cost: The anodizing process is mature, and the processing cost is significantly lower than that of tungsten carbide or ceramic coated rollers, making it suitable for small and medium-sized production lines with limited budgets.

Environmental compatibility: There is no heavy metal pollution during the oxidation process, and the waste liquid is easy to treat, which is in line with the trend of green manufacturing.

application area

1. Printing and packaging industry

Offset/gravure rollers: High surface finish ensures even ink transfer.

Coating roller: used for coating lithium battery separators and optical films to avoid material adhesion.

Food packaging roller: corrosion-resistant and hygienic, safe in contact with food ingredients.

2. Textile and paper industry

Guide roller/tension roller: Lightweight reduces energy consumption and is resistant to fiber wear.

Hot press roller: fast thermal conductivity, uniform temperature transfer (such as non-woven fabric hot rolling).

3. Electronic manufacturing

Copper clad laminate laminating roller: Insulation prevents short circuits in the circuit.

Display screen optical film roller: ultra-high cleanliness to avoid screen defects.

4. Laser processing and 3D printing

Laser engraving roller: fast heat dissipation, resistant to high temperature laser ablation.

Powder feeding roller: anti-static to prevent metal powder from adhering.

|