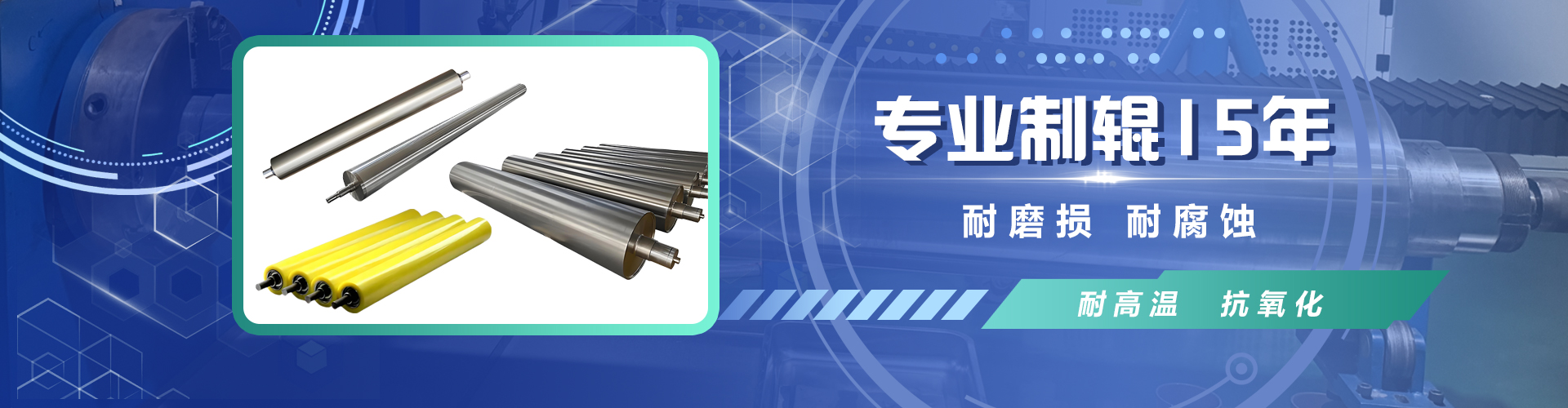

Roll Manufacturing Division

Focus on roller products, professional roller manufacturing, and quality assurance

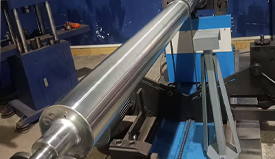

Osonai Company has been specializing in roller manufacturing, introducing German technology and specializing in the production of various rubber rollers, aluminum rollers, and customized non-standard rollers for industrial use. The company has advanced processing equipment at home and abroad, including CNC lathes, milling machines, high-frequency heating machines, automatic welding machines, CO2 protection welding machines, polishing machines, mirror polishing machines, grinders, mixing machines, fully automatic winding and wrapping machines, automatic glue filling machines, vulcanization tanks, medium and high grinding machines, high-precision cylindrical grinders, dynamic balancing machines, etc. We have advanced experimental and testing equipment, as well as strict testing procedures.

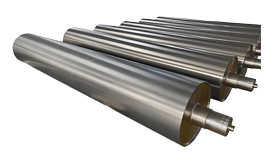

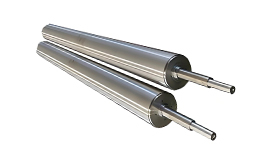

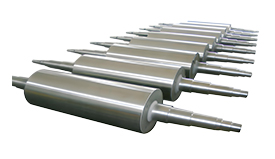

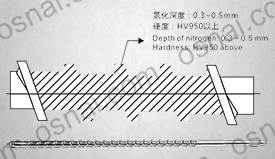

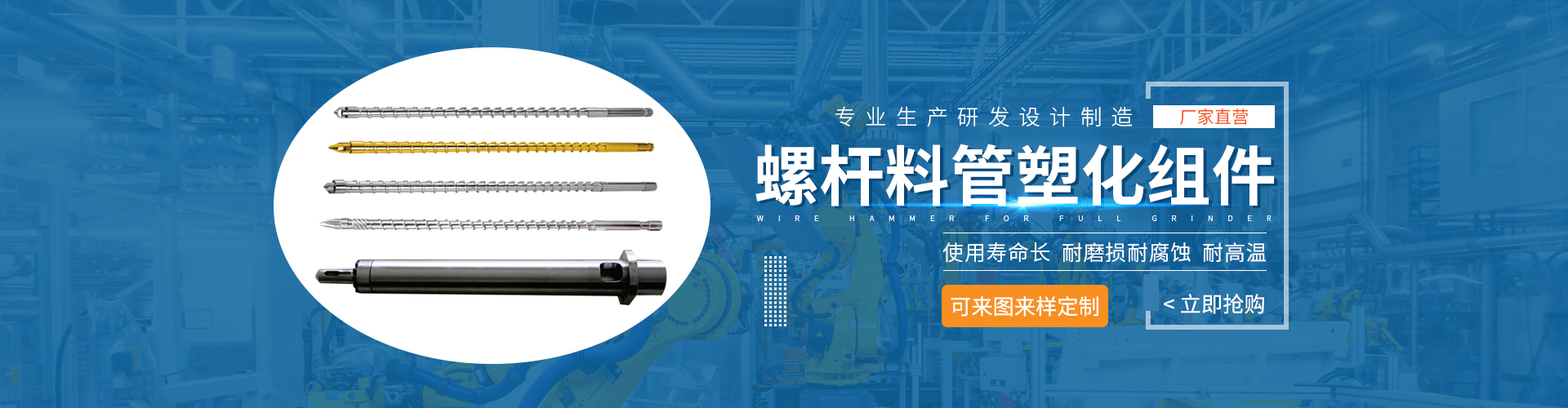

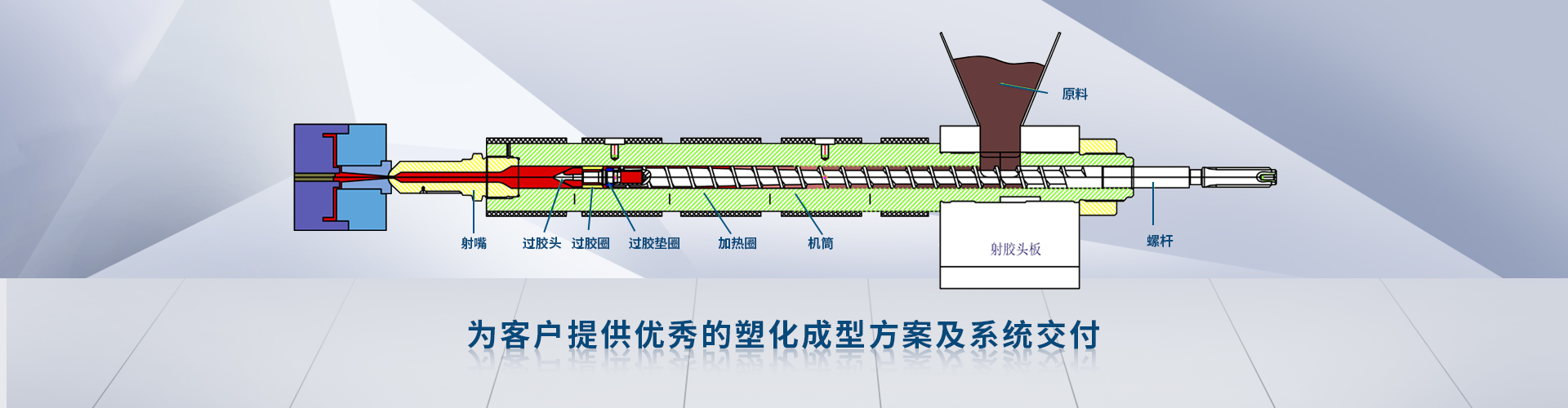

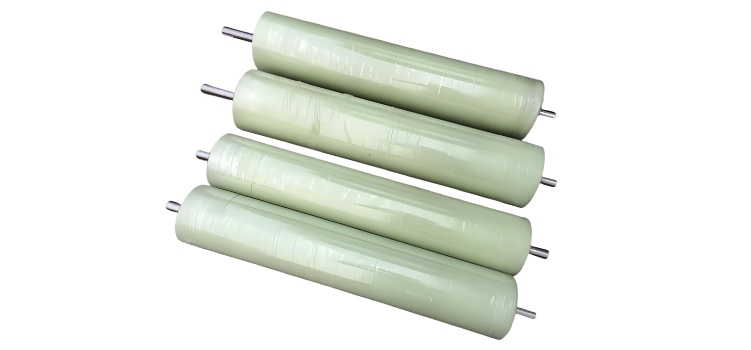

Osonai specializes in the production and manufacturing of steel rollers, including tungsten carbide rollers, quenched rollers, chrome plated rollers, stainless steel pipes, aluminum rollers, anodized aluminum rollers, mirror rollers, tension rollers, fixed guide rollers, flattening rollers, guide rollers, driving rollers, driven rollers, clamping rollers, pinch rollers, roller bodies, knife groove rollers, flattening rollers, roller sleeves, auxiliary rollers, corona water cooling rollers, conductive rollers, ceramic rollers, conveyor rollers, PTFE rollers, ceramic rollers, heating rollers, mesh rollers, etc;

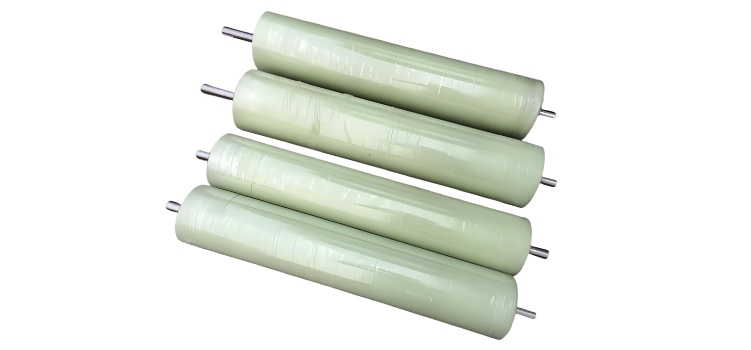

Rubber rollers: hydrogenated nitrile rubber rollers, polyurethane rubber rollers, carbon fiber rollers, composite material rubber rollers, EPDM rubber rollers, silicone rubber rollers, fluororubber rollers, butyl rubber rollers, natural rubber rollers, chloroprene rubber rollers, wool rollers, oil extrusion rollers, anodized aluminum rollers, functional rollers, etc;

Various types of rollers are widely used in industries such as lithium batteries, aluminum processing, metallurgy, papermaking, packaging, leather, printing and dyeing, textiles, films, plastics, and construction machinery. It can meet customers' requirements for wear resistance, high temperature resistance, oil resistance, solvent resistance, high pressure resistance, high speed, acid and alkali resistance, and can be customized according to drawings and samples.

Elastic composite material rubber rollers have the following core advantages:

1、Excellent mechanical performance

High strength tear resistance: The tensile strength is significantly higher than that of ordinary rubber, especially suitable for heavy-duty scenarios such as mining scrapers

Wide hardness range: adjustable from Shore A10 to D70, which can meet the softness requirements of printing rollers and the high hardness requirements of rolling steel rollers

Excellent dynamic performance: high rebound characteristics combined with good low-temperature performance (maintaining flexibility at -50 ℃), suitable for precision working conditions such as hydraulic sealing

2、Outstanding durability features

Superior wear resistance: Its wear resistance is 5-10 times that of natural rubber, especially suitable for friction conditions with water/oil lubrication

Chemical corrosion resistance: It has special resistance to oils, diesel, lubricants, etc., but should avoid contact with strong solvents such as acetone

Environmental stability: Strong UV/ozone tolerance, with a size change rate of less than 1% in humid or rapidly changing environments

3、Special functional performance

Excellent surface performance: The colloid is fine and smooth, and the ink transfer efficiency is increased by more than 30% compared to ordinary rubber, significantly improving printing quality

Wide temperature adaptability: The heat resistance of the polyester MD system can reach 150 ℃, while the polyether system also has hydrolysis resistance

Flexible molding process: supports multiple processing methods such as casting and molding, with short demolding time and high yield of finished products

4、Economic advantage

Long lifespan: In scenarios such as coal selection vibrating screens, the service life can reach 3-5 times that of metal materials

Low maintenance cost: Its fatigue resistance makes it less prone to cracking during high-frequency bending applications, reducing the frequency of downtime and replacement

Main application areas

1、Printing industry

2、Textile printing and dyeing industry

3、Grain processing field

4、Metallurgical industry

5、Other key areas:

automobile making

Architecture and Mining

Plastic Process

|