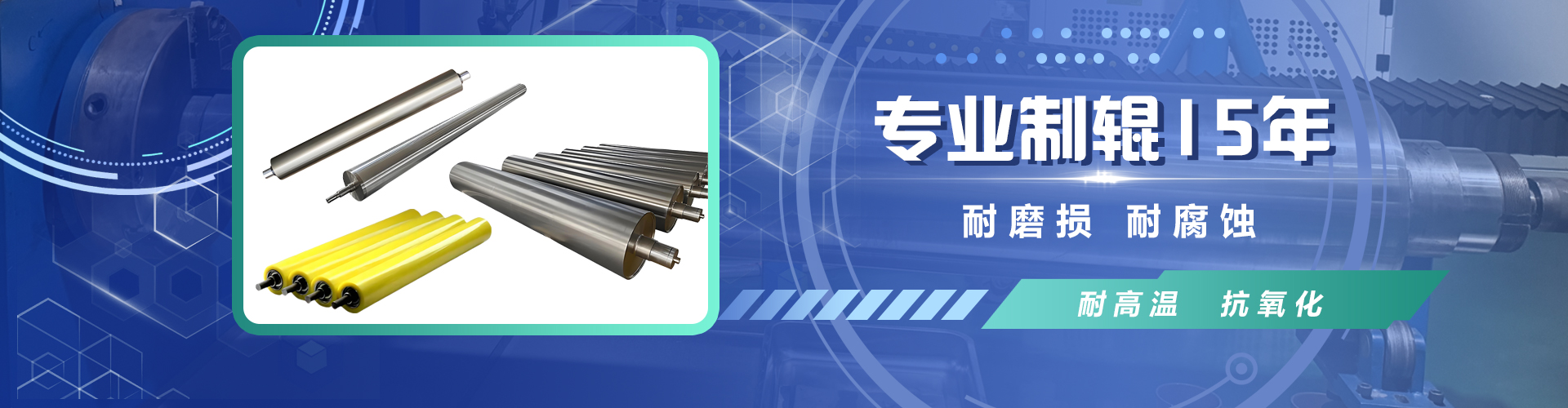

Roll Manufacturing Division

Focus on roller products, professional roller manufacturing, and quality assurance

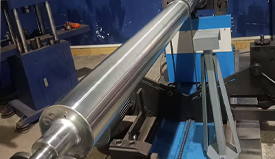

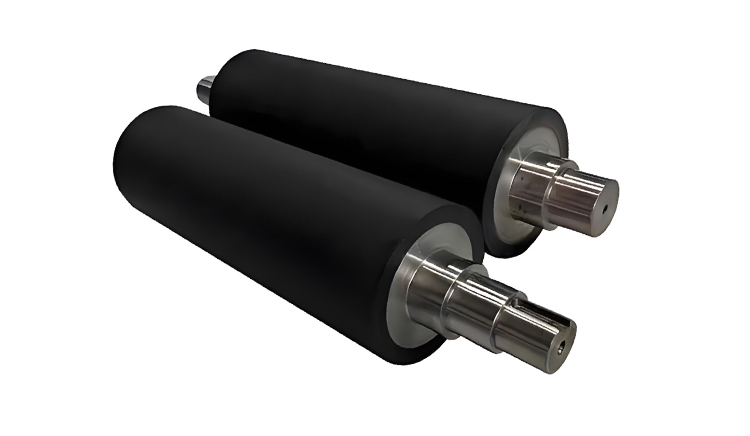

Osonai Company has been specializing in roller manufacturing, introducing German technology and specializing in the production of various rubber rollers, aluminum rollers, and customized non-standard rollers for industrial use. The company has advanced processing equipment at home and abroad, including CNC lathes, milling machines, high-frequency heating machines, automatic welding machines, CO2 protection welding machines, polishing machines, mirror polishing machines, grinders, mixing machines, fully automatic winding and wrapping machines, automatic glue filling machines, vulcanization tanks, medium and high grinding machines, high-precision cylindrical grinders, dynamic balancing machines, etc. We have advanced experimental and testing equipment, as well as strict testing procedures.

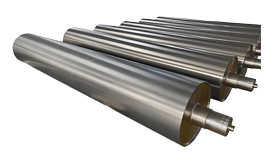

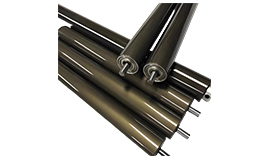

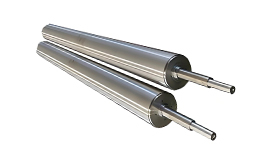

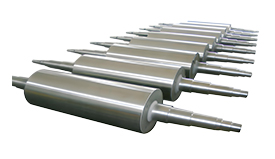

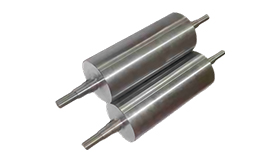

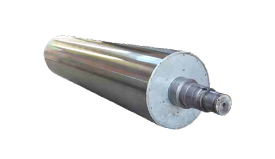

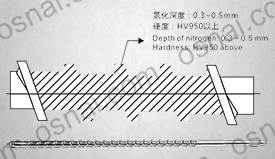

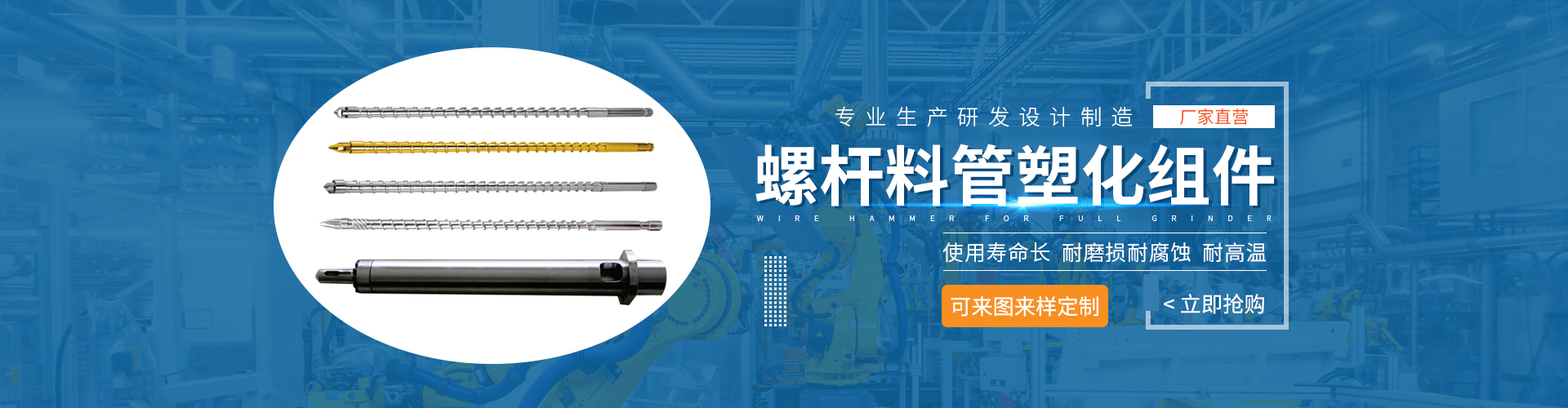

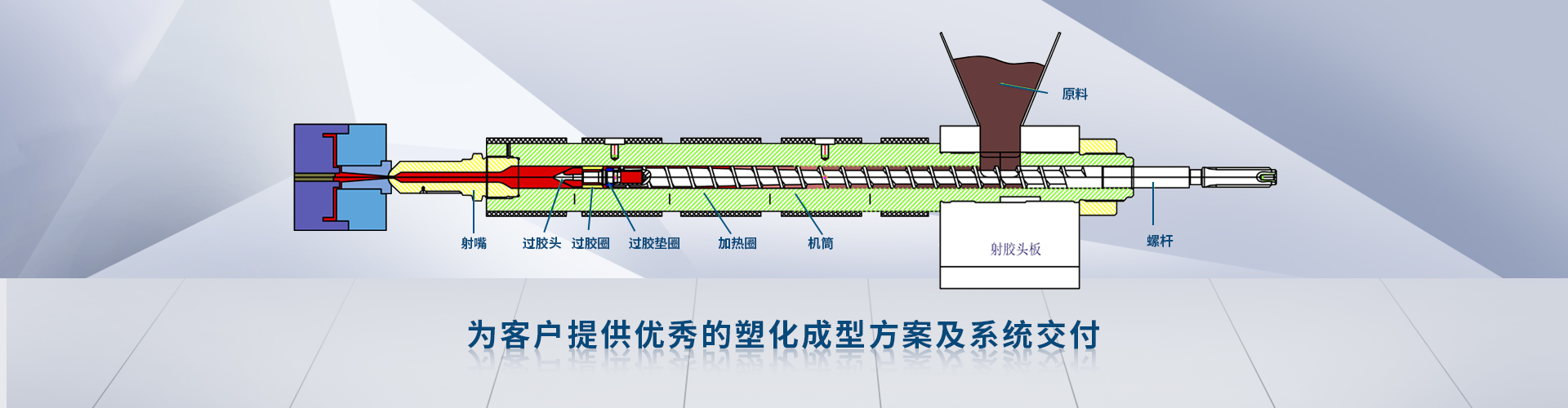

Osonai specializes in the production and manufacturing of steel rollers, including tungsten carbide rollers, quenched rollers, chrome plated rollers, stainless steel pipes, aluminum rollers, anodized aluminum rollers, mirror rollers, tension rollers, fixed guide rollers, flattening rollers, guide rollers, driving rollers, driven rollers, clamping rollers, pinch rollers, roller bodies, knife groove rollers, flattening rollers, roller sleeves, auxiliary rollers, corona water cooling rollers, conductive rollers, ceramic rollers, conveyor rollers, PTFE rollers, ceramic rollers, heating rollers, mesh rollers, etc;

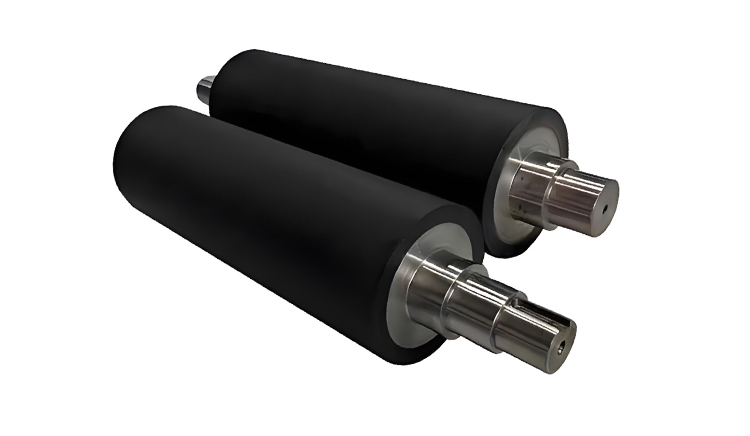

Rubber rollers: hydrogenated nitrile rubber rollers, polyurethane rubber rollers, carbon fiber rollers, composite material rubber rollers, EPDM rubber rollers, silicone rubber rollers, fluororubber rollers, butyl rubber rollers, natural rubber rollers, chloroprene rubber rollers, wool rollers, oil extrusion rollers, anodized aluminum rollers, functional rollers, etc;

Various types of rollers are widely used in industries such as lithium batteries, aluminum processing, metallurgy, papermaking, packaging, leather, printing and dyeing, textiles, films, plastics, and construction machinery. It can meet customers' requirements for wear resistance, high temperature resistance, oil resistance, solvent resistance, high pressure resistance, high speed, acid and alkali resistance, and can be customized according to drawings and samples.

1. Excellent high temperature resistance

Long term working temperature can reach 150 ℃ (ordinary NBR is only 100 ℃), short-term tolerance * * 180 ℃ * *, suitable for high temperature steam or hot oil environment.

2. Super strong oil resistance and chemical corrosion resistance

The tolerance to fuel, lubricating oil, hydraulic oil, and acid/alkali media is better than NBR, especially suitable for oils containing sulfur and extreme pressure additives.

3. Excellent anti-aging and ozone resistance

The hydrogenation structure significantly reduces double bonds, with UV and ozone resistance similar to EPDM, and extends outdoor service life by 3-5 times.

4. High mechanical strength and wear resistance

The tensile strength can reach over 30MPa, and the wear resistance is 50% higher than NBR, making it suitable for high-pressure compression scenarios.

5. Low temperature elasticity retention

The glass transition temperature (Tg) is as low as -40 ℃ (ordinary NBR is -20 ℃), and it still maintains flexibility in cold environments.

Main application areas

Automobile manufacturing and maintenance, food and pharmaceutical equipment, petrochemicals and energy, printing and coating industry, special industries

For example, working rolls or support rolls in cold/hot rolling mills, conveyor rolls or guide rolls on coating and plating production lines, conveyor rolls for cleaning and surface treatment, buffer rolls or guide rolls for stamping and forming, and conveyor rolls on continuous annealing production lines; High temperature printing, lithium battery separator coating, optical film coating, optical backplate coating, conductive silver paste coating, waterproof layer coating;

Hydrogenated nitrile rubber spokes, with their balanced heat resistance, oil resistance, and mechanical properties, have become an "all-around" choice in harsh industrial environments, especially in high-end fields such as automobiles and energy, which cannot be replaced. When selecting, it is necessary to strictly evaluate the type of medium, temperature range, and dynamic load conditions.

|